Which Type of Home Insulation is Best ?

Shopping for home insulation is often confusing for homeowners who simply want the most cost effective way to improve indoor comfort and reduce energy waste.

It’s not hard to tell if you can benefit from adding insulation. Are your utility bills higher than your neighbors? Even with a thermostat programmed for 68 in the winter and 78 in the summer? Are one or more rooms too hot in the summer and too cold in the winter?

What is confusing to most homeowners (and many construction professionals) is the choice of which type of insulation– fiberglass, cellulose or spray foam. All three materials can achieve the same performance when installed correctly. For existing homes, the choice will depend of the existing insulation, location of heating and cooling equipment, budget and pay-back.

The most important factor in purchasing quality insulation for your home is the contractor, not the material. For insulation to work, it must be installed properly, but how can a homeowner tell if the job is done right? The AlabamaWISE program includes work quality standards that participating contractors have committed to achieve. The work is verified by quality assurance inspections.

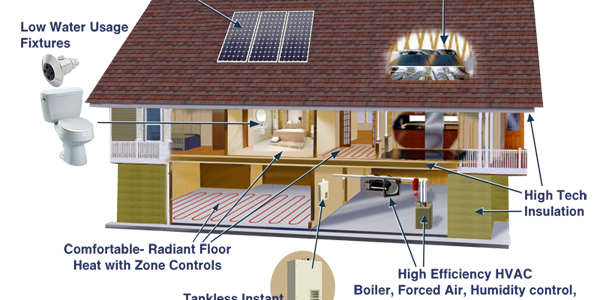

The Thermal Boundary keeps the conditioned air inside the home. Note attached garage is kept outside the thermal boundary for energy conservation and indoor air quality.

A quality insulation job creates a thermal boundary between conditioned space and unconditioned space. The most important features of the thermal boundary are:

- Insulation and Air Barrier in alignment

- Continuous, even, uninterrupted around the entire building enclosure

Fiberglass and cellulose insulation are not air barriers and must be aligned with another material to prevent air movement through the insulation. In most homes, the air barrier includes: drywall, framing, sheething, rigid insulation board, spray foam insulation, and building wrap.

Spray foam insulation is an air barrier, but it must be installed properly to meet the air-sealing goal. Many spray foam contractors don’t achieve all the air sealing benefits in existing homes because they miss hard-to-reach areas.

R-Value is the measure of a material’s resistance to conductive heat flow. R-value is often given per inch of thickness. Open cell spray foam is R-3.6 per inch, cellulose is R-3.7 per inch, loose-fill fiberglass is R-2.5 per inch.

Beware of claims of “Effective R-Value”. The Federal Trade Commission has rules about R-Value claims to protect consumers under 16 CFR 460.5 – “The R-value Rule covers all ‘‘home insulation products.’’ Under the Rule, ‘‘insulation’’ is any product mainly used to slow down the flow of heat from a warmer area to a cooler area, for example, from the heated inside of a house to the outside during the winter through exterior walls, attic, floors over crawl spaces, or basement. ‘‘Home insulation’’ includes insulation used in all types of residential structures. R-value measures resistance to heat flow. R-values given in labels, fact sheets, ads, or other promotional materials must be based on tests designed by the American Society of Testing and Materials (ASTM). “

Adding insulation to an existing home should start with assessing the existing thermal boundary (insulation and air-barrier alignment):

- Where is the Thermal Boundary located?

- What is the existing R-Value?

- How much existing Air Leakage?

Locating Thermal Boundary can be tricky in large, complex homes with lots of architectural features. Double walls, dropped soffits, modern fireplaces, chases, vaulted ceilings, bonus rooms, finished attics, dormers, cantelievers, attached garages, and basements are always problems areas.

Check the insulation in your attic first. If the ceiling framing is visible, you need more insulation. Wall insulation is difficult and expensive to upgrade unless included as part of another renovation, such as new siding. Then additional insulation can be added to wall cavities. Under-floor insulation usually needs improvement.

Air leakage should be measured with a blower-door test before and after adding insulation and air sealing the home. Blower door testing is a standard part of the AlabamaWISE home performance assessment by participating contractors.

A fiberglass or cellulose attic insulation job includes air sealing and attic ventilation with soffits, ridge vents and gable vents to let out the summer heat. Do not use power attic ventilators because they waste energy. AlabamaWISE home performance contractors take a systems approach to each job and will evaluate proper attic ventilation and air leaks from inside the home during the inspection.

If your HVAC system or ducts for heating and cooling are located in the attic, you may want to consider spray foam to encapsulate the attic for optimal energy efficiency. This will be the most expensive option, so be sure to have an energy evaluation to estimate cost savings. If you don’t have a heating and air conditioning system in the attic, air sealing and blown-in fiberglass will probably be the most cost-effective insulation solution.

Cellulose is considered the “green” insulation choice because it’s made from recycled newspaper treated with borate to resist insects, mold and fire. The attic should be well sealed to prevent cellulose “dust” from entering the home. Fiberglass requires more energy to manufacture, but can include recycled glass. Spray foam insulation emits gas during installation that requires a protective respirator.

[DKB url=”/home-energy-audits” text=”Get Unbiased Advice on Efficient Home Improvements” desc=”Start Saving NOW with an Energy Assessment” title=”Get Started with AlabamaWISE” type=”large” color=”green” width=”250″ opennewwindow=”yes”]

Comments are closed.